Industrial facilities contain many hazards that can affect worker health and safety, including everything from slippery floors and dangerous machinery to chemical fumes and biological contaminants. While engineering controls and safety practices aim to directly control these hazards, according to the experts at All Pro Cleaning Systems (allprocleaningsystems.com) industrial cleaning also plays a key role in protecting workforces.

Reducing Slips, Trips and Falls

Floors become major safety hazards when contaminated with water, oil, dust, and debris. These substances cause surfaces to become slick and uneven, leading to slips and trips. Employers can optimize floor cleaning to minimize fall risks. Effective floor cleaning is crucial in an industrial setting where spills are common and heavy machinery raises risks. Clean, dry floors are essential for safe foot travel.

Removing Respiratory Irritants

Airborne particulates are a common hazard in facilities with dust, fumes, or aerosols. Inhaling these materials can cause respiratory irritation or worse. Meticulous cleaning removes dust and other hazardous particles from the air. Preventing recontamination is also key. Enforce strict cleaning schedules so dust and grime don’t re-accumulate. Air quality testing can identify any lingering particulate hazards.

Clearing Chemical Vapors

Volatile organic compounds (VOCs) off-gas from many liquids, adhesives, solvents, and coatings used industrially. VOCs create potential health hazards when inhaled, so proper cleaning limits VOC exposure.

Cleaning spills quickly also prevents concentrated vapors from accumulating in work areas. Routine inspections should assess chemical storage and actively check for any unusual odors.

Preventing Biological Contamination

Bacteria, viruses, mold, and fungi thrive in damp, dirty spaces. These biological contaminants create health risks for workers and can even damage equipment through microbial corrosion. Careful cleaning and disinfection limits biohazards, while routine microbial testing identifies problem areas needing intervention. Monitoring for organisms like Legionella in water systems prevents outbreaks.

Avoiding Cross Contamination

When cleaning industrially the process itself can spread hazards if proper precautions aren’t taken. Pathogens, irritants, and other dangers can be carried on cleaning supplies and spread around. Proper training ensures cleaning staff learn processes to avoid unintended contamination while working.

Safe Chemical Handling

Industrial cleaners contain harsh caustic, acidic and toxic substances. Safely handling these chemicals protects workers from burns, poisoning and hazardous fume exposure. Ensure anyone using cleaners is fully trained. Providing adequate secure storage keeps cleaning chemicals away from work areas when not in active use. Post warning signs if spaces were recently treated with hazardous cleaners.

Maintaining Safety Gear and Equipment

Industrial machinery, power tools, rigging, ladders, safety harnesses and other gear all require cleaning and maintenance. Dirt, debris, and grime on equipment can create safety risks for users, while corrosion undermines integrity and performance.

Proactive cleaning extends the usable life of assets. Equally important, it ensures equipment operates safely without dangerous malfunctions. Workers who inspect and clean their own gear keep potential hazards visible and under control in between deep cleanings by maintenance staff.

Instilling a Culture of Cleanliness

Ultimately, occupational health depends on more than just routine deep cleaning. Fostering an overall culture of workplace cleanliness and safety is vital.

Provide supplies like disinfectant wipes and cleaning sprays for workers to quickly clean their immediate area. Empower teams to identify and resolve hygiene and contamination issues rather than simply relying on outside janitorial staff.

Train everyone on maintaining tidy workstations and practicing basic surface cleaning. Include cross-contamination risks in training so workers recognize how their practices affect others.

Conclusion

Through proactive cleaning procedures and ingraining a culture of workplace cleanliness, companies can protect their personnel from the many health hazards found in industrial work. Workers also feel valued in a setting kept clean for their well-being. The investment in proper industrial cleaning delivers significant returns in a safer, healthier, and more productive workforce.

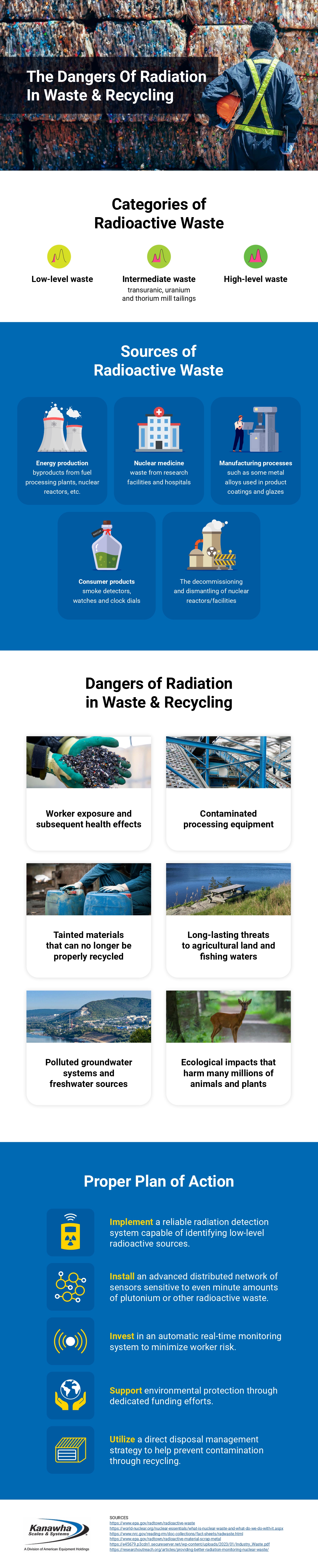

Hazardous materials can find their way into recycling, posing a danger to workers. To learn more on the dangers of radiation in waste and recycling, please see the accompanying resource.

Infographic provided by truck scales experts, Kanawha Scales & Systems